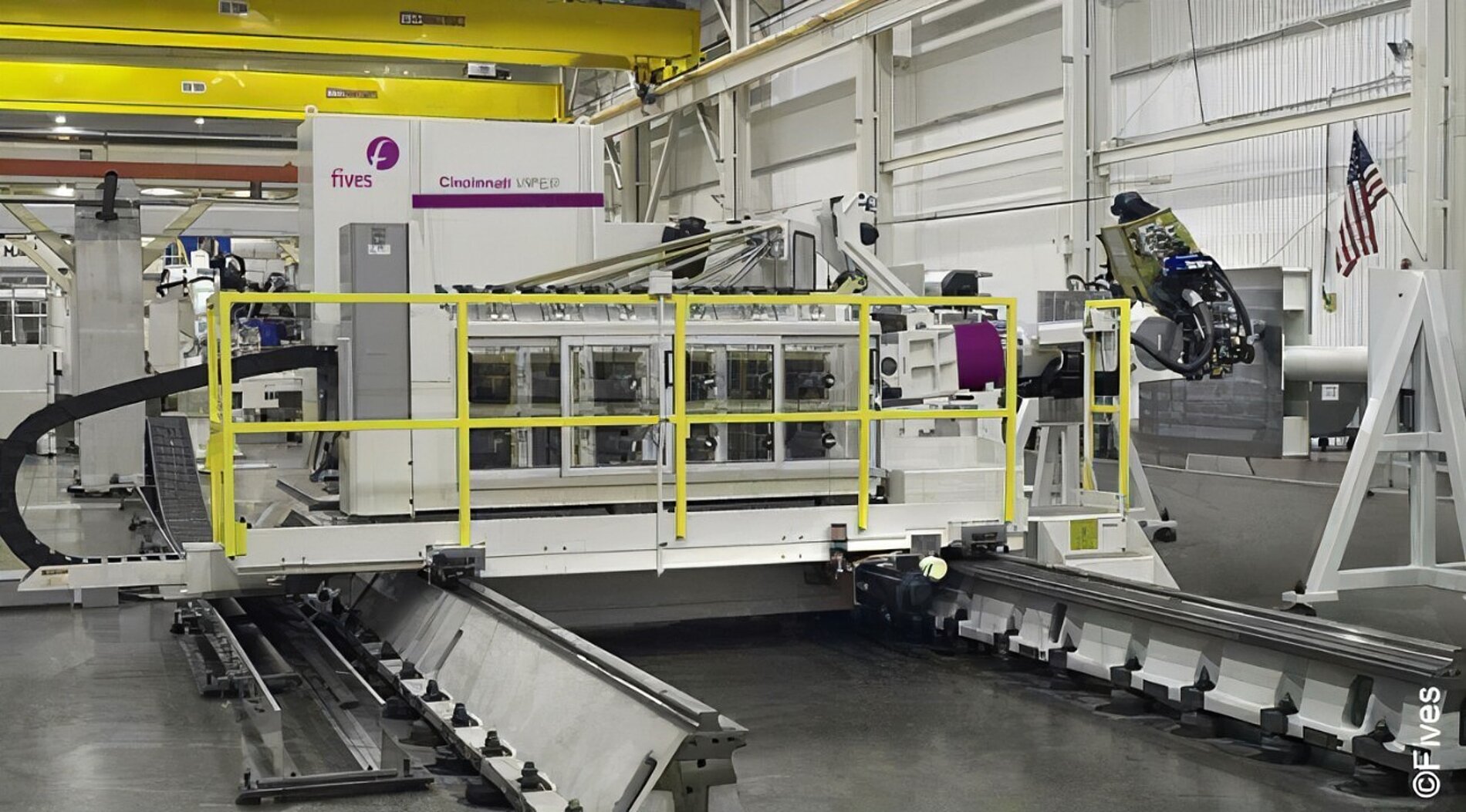

For optimum automated fiber placement, you need a machine that can handle complex shapes and surfaces with precision and efficiency. The Cincinnati VIPER? combines dexterity, flexibility and accuracy to achieve unrivalled performance.

Our VIPER? range can accommodate part diameters of up to 8 m. In-process compaction on all models ensures optimum consolidation, while our Cut-Clamp-Restart system guarantees highest reliability – minimizing waste. In short: VIPER? machines deliver in the ways that matter most.

VERSATILE AND ADVANCED FIBER PLACEMENT

The high-performance Cincinnati VIPER? 1200 efficiently produces superior quality convex and concave parts up to 2 m in diameter.

FIBER LAYING

FOR LARGER PARTS

The Cincinnati VIPER? 6000 brings the same advantages as the VIPER? 1200 – on a bigger scale. It brings versatility and productivity to parts up to 8 m diameter.

TAKING AUTOMATION

TO THE NEXT LEVEL

With the Cincinnati Robotic VIPER?, we’re automating jobs that were previously only possible by hand. It’s compact and low-maintenance. And with in-process inspection, accuracy and speed are guaranteed.