Cranfield Precision has a global reputation for ultra-precision machining with decades of customer references in the optics, optical film, medical and aerospace industries. Get the benefit of our experience and talk to us about your ultra-precision machining needs.

Engineering partnerships with Cranfield Precision

Located in Bedford, UK, Cranfield Precision? teams have over 50 years of experience in precision machine design and manufacture of world-leading ultra-precision machines. The business area encompasses ultra-precision machine tools, precision measuring systems and custom designed special purpose machines.

The strong links to university research groups and trade associations give Cranfield Precision? the capacity to undertake projects ranging from R&D and process consultancy to complete machine design and manufacture.

Check out our Engineering Partnership brochure to learn more about our available offers.

ACCOMPLISHMENTS INCLUDE:

- Pioneers of ductile regime grinding, ELID grinding and diamond turning

- World’s first ductile regime silicon wafer edge grinding machines

- World’s first diamond turning machine for LCD brightness enhancement film production

- Metrology systems for NASA’s Chandra space telescope mirrors

- CNC development, enabling the world’s first CNC controlled cam and crank grinding machine

- World-leading large optics grinding machine for the production of the next generation Extreme Ultraviolet (EUV) silicon wafer lithography system mirrors

Machine – Process – Partnership

Every application is different, which is why you need an expert technical partner to support your ultra-precision machining goals. Our services fall into three main categories:

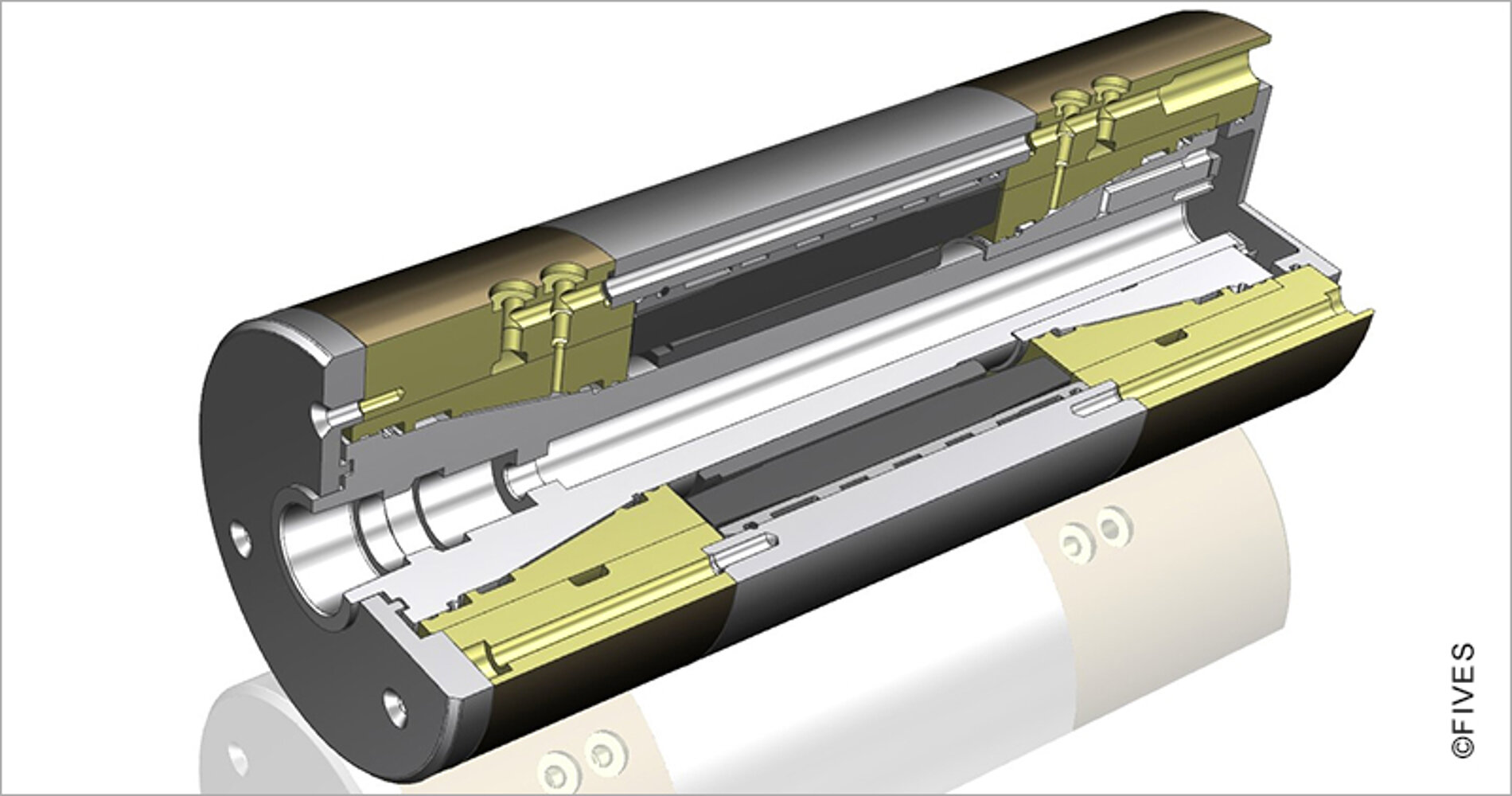

MACHINING PROCESS DEVELOPMENT

Gain access to our facilities, resources and ultra-precision development machines and collaborate with us to improve your machining processes and develop new, market leading products.

- Develop a new product

- Improve your component specification

- Solve a complex toolpath problem

- Try new processes

- Reduce your R&D overhead

- Free up your machinery for production

View our case study on process development for optical molds

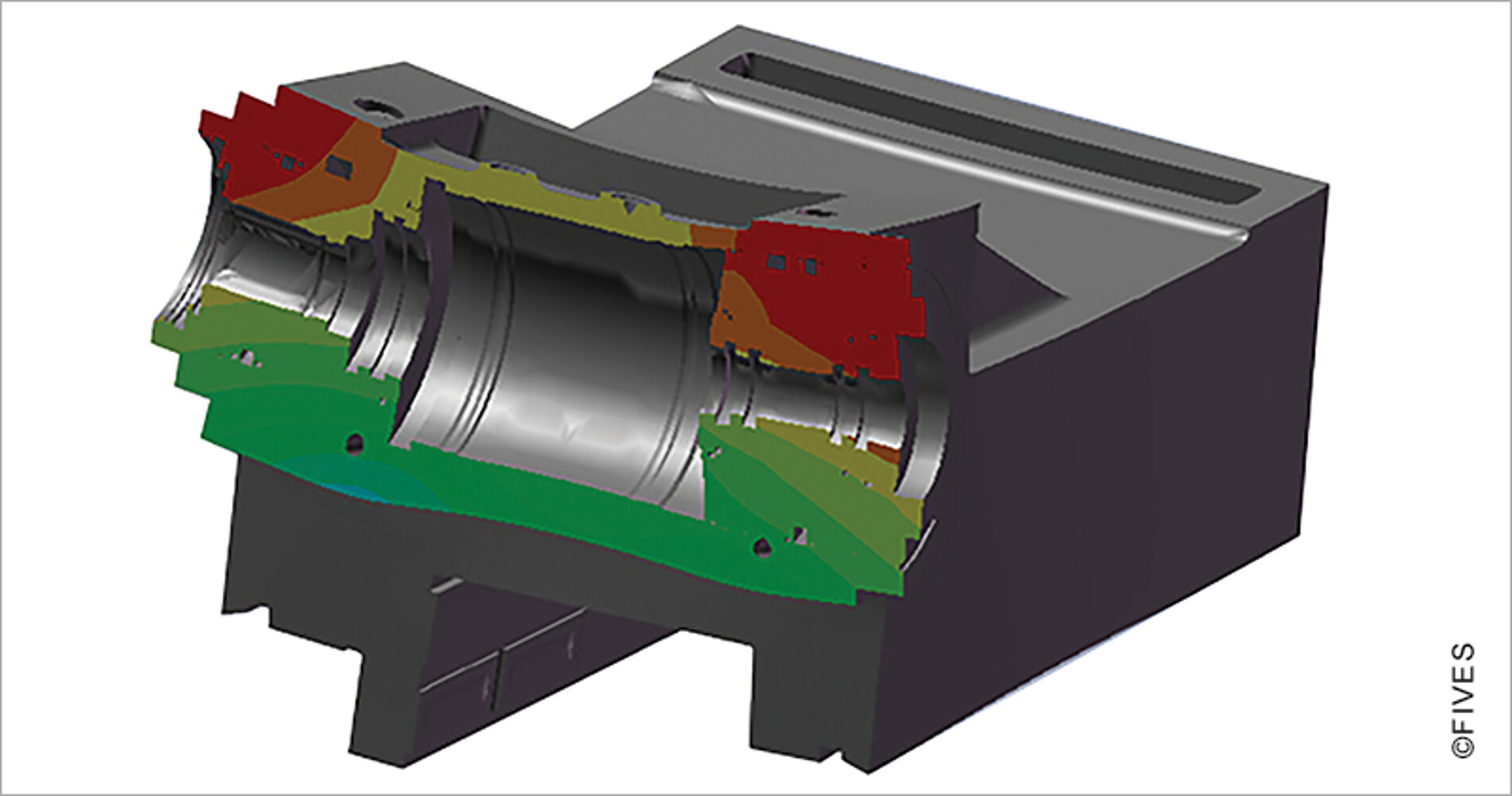

PROCESS TECHNOLOGY IMPROVEMENT

With over 50 years’ experience in ultra-precision machine and process development, let Cranfield Precision work with you to employ proven analysis and design techniques to enhance your capabilities.

- Solve production problems

- Update old production equipment

- Enhance your software capabilities

- Make high quality parts

- Improve your machine capability

- Develop a new manufacturing process

View our case study on process technology for improved thermal control

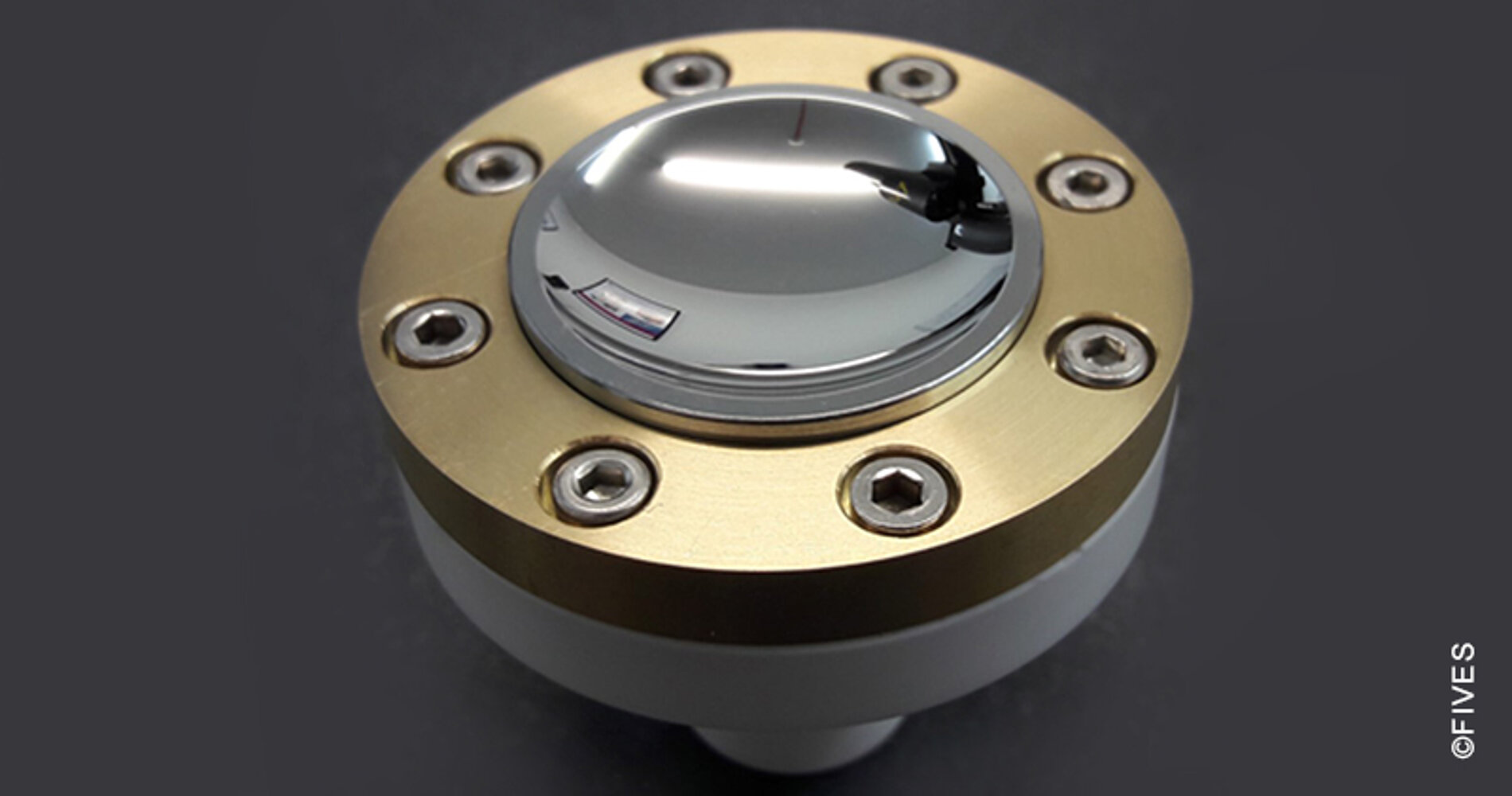

PRECISION DESIGN

Develop a specification with Cranfield Precision and collaborate to produce an ultra-precision design to your requirements. Our assembly facilities can even manufacture prototype, production and batch machines for you.

- Design complex components

- Upgrade existing machines or sub-assemblies

- Solve work holding problems

- Develop new software solutions

- Improve your machine capability

- Create bespoke machines

View our case study on precision design for vertical counterforce

Tap into our ultra-precision machining expertise

Make the most of our engineers and experience to design solutions that meet your needs. Contact us to get started on your customized solution today.