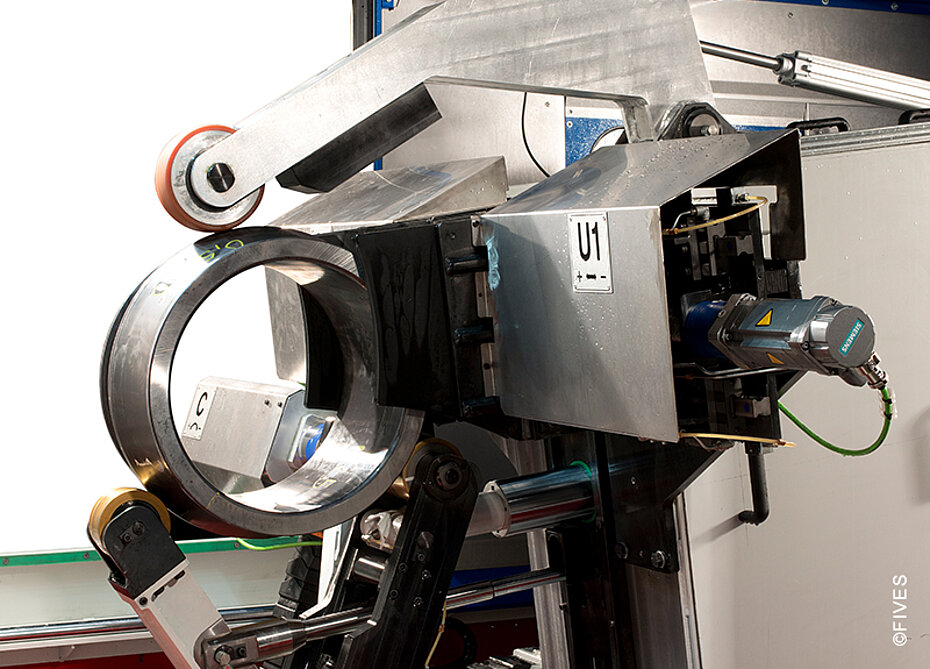

Our reliable horizontal double disc grinders for flat and parallel surfaces are available in a range of sizes. A smooth and consistent grind is always guaranteed thanks to the exceptional stiffness of the machines. The result? High stock removal, reliable repeatability and reduced cycle time.

Your high-volume horizontal double disc grinding solution

With up to 98% uptime, our Horizontal Double Disc (HDD) machines provide a robust solution for both flat and parallel surface grinding applications. Highly efficient, with exceptional stiffness and flexibility, these machines are an engineered, turnkey solution for your grinding needs.

Check out our Horizontal double disc flyer to learn more.

Gardner, Giustina or Daisho grinding machines will be proposed according to the standards in the specific geographical areas.

Flexibility - Precision - Quality

With our exceptional engineering, you don’t have to choose quality over quantity. Our HDD machines are designed for flexibility and speed, without sacrificing surface quality.

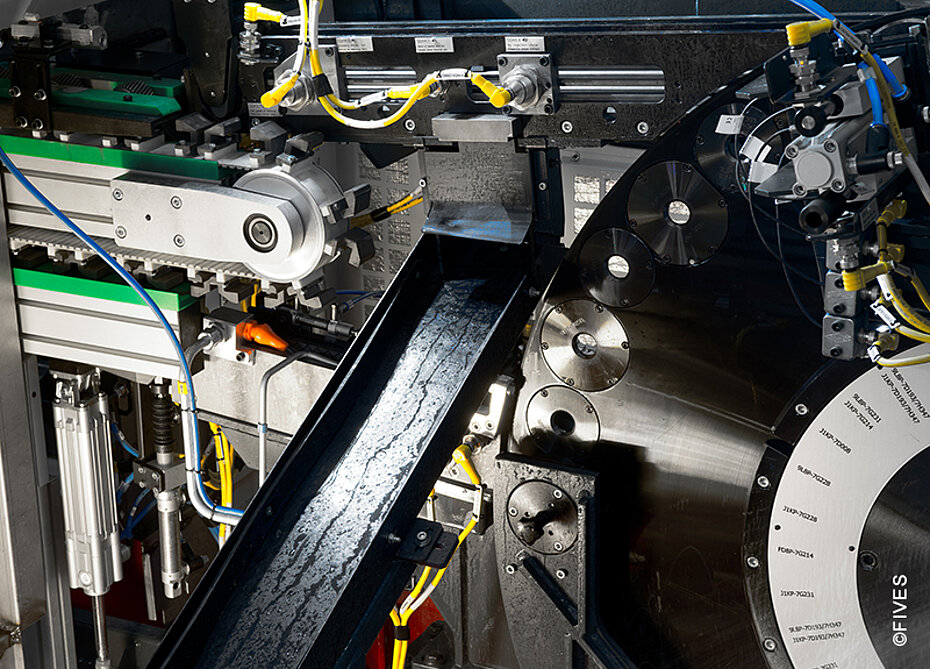

Automatic loading/unloading options are also available, which enables a fast changeover. As a result, one machine can be used for multiple operations.

MACHINE HIGHLIGHTS

The modular setup enables engineered solutions, developed specifically for your production requirements. Additional key benefits include:

- Grinding wheels are available with diameters from 305 – 1,067 mm

- Choose from various power output options for wheel motors

- Suitable for through-feed or plunge feed working methods

- Automatic, semi-automatic or manual loading/unloading options available

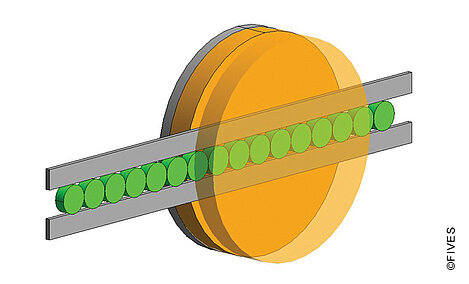

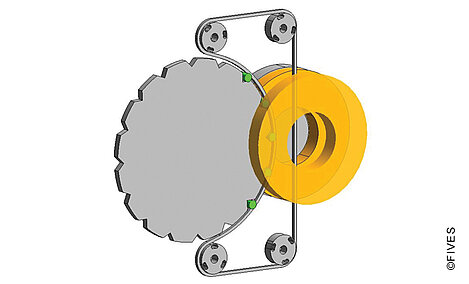

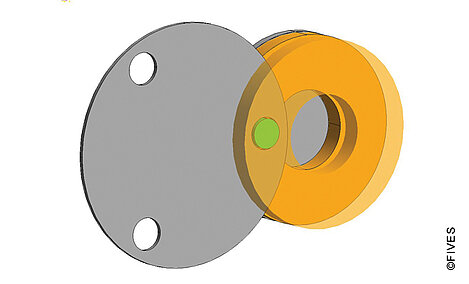

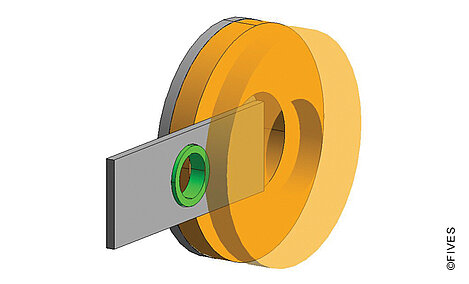

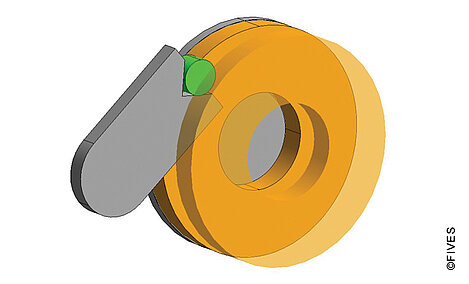

Linear through-feed

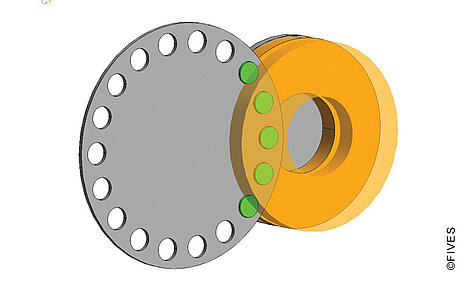

Rotary through-feed

Rotary carrier with wire clamp

Index carrier

Reciprocating feeder carriage

Swing arm

VARIOUS WORKING MODES

Our HDD machines are used to surface grind components with different working methods that include:

Horizontal Double Disc Grinder

Highly efficient, with exceptional stiffness and flexibility, these machines are engineered, turnkey solutions. Applications include bearings, brake & clutch discs, compressor plates, connecting rods, covers, flanges, gears, inner/outer rings and various other components.

specifications

| HDD610 | HDD760 | HDD915 | HDD1067 | |

| MACHINING CAPACITY | ||||

Max. workpiece OD | 300 mm | 400 mm | 800 mm | 1,000 mm |

Max. workpiece width (Infeed) | 1 - 90 mm | Δ between min. max.: 230 mm | Δ between min. max.: 230 mm | Δ between min. max.: 230 mm |

| Max. workpiece width (Through-feed) | N/A | 2.5 - 60 mm | N/A | N/A |

| wheelHEAD | ||||

Wheel diameter | 610 mm | 760 mm | 915 mm | 1,067 mm |

Max. power | 22 kW | 75 kW | 75 kW | 75 kW |

| LINEAR AXES | ||||

Positioning resolution | 1 μm | 1 μm | 1 μm | 1 μm |

| Dimensions | ||||

Dimensions (W x D x H) | 3,600 x 2,600 x 2,150 mm | 4,800 x 5,000 x 2,450 mm | 4,800 x 5,000 x 2,450 mm | 4,800 x 5,000 x 2,450 mm |

Machine weight | 6,000 kg | 14,000 kg | 14,000 kg | 14,500 kg |

| HDD610 | HDD760 | HDD915 | HDD1067 | |

| MACHINING CAPACITY | ||||

Max. workpiece OD | 11.8" | 15.8" | 39.4" | 39.2" |

Max. workpiece width (Infeed) | 0.04" - 3.5" | Δ between min. max.: 9" | Δ between min. max.: 9" | Δ between min. max.: 9" |

| Max. workpiece width (Through-feed) | N/A | 2.5 - 60 mm | N/A | N/A |

| wheelHEAD | ||||

Wheel diameter | 24" | 30" | 36" | 42" |

Max. power | 22 kW | 75 kW | 75 kW | 75 kW |

| LINEAR AXES | ||||

Positioning resolution | 1 μm | 1 μm | 1 μm | 1 μm |

| Dimensions | ||||

Dimensions (W x D x H) | 11.8' x 8.5' x 7.1' | 15.8' x 16.4' x 8' | 15.8' x 16.4' x 8' | 15.8' x 16.4' x 8' |

Machine weight | 13,228 lb | 30,865 lb | 30,865 lb | 31,967 lb |