天博体育 to Attend JEC World 2025

天博体育 will be attending , the leading international composites show, in Paris-Nord Villepinte on March 4-6, 2025. Visit booth 5L58 to discover the innovative solutions that make 天博体育 your single source provider of Composites & Automated Solutions.?

The 天博体育, Composites & Automated Solutions business line provides end-to-end composite manufacturing solutions from lamination to demolding and everything in between. As industry partners, we provide customizable lamination, forming, inspection, and curing solutions. Precision and performance are at the heart of everything we do, ensuring minimal waste and maximum quality. We specialize in developing highly automated end-to-end solutions that increase productivity across the complete line.

This automation specialism has led us to develop a range of unique, customized automation solutions. Working in diverse fields such as aerospace and biomedical engineering, we are problem solvers on the broadest scale. This innovation mindset is applied to all our projects – composite or other, big or small. Comprised of renowned legacy names: Cincinnati, Forest-Liné, and Lund we're responsible for the largest install base of tape layer and fiber placement machines in the world.

We will be hosting DAILY Tech Talks on various solutions to industry challenges in the booth throughout the week. Don't miss out!

Flexible Robotic Fiber Placement for Complex Composite Structures

As aerospace designs evolve, manufacturers face the challenge of efficiently producing complex composite components without compromising quality. Discover how our advanced robotic fiber placement system offers unparalleled flexibility and precision, enabling the seamless production of intricate parts. Learn how this technology addresses industry demands for reduced waste, increased throughput, and superior structural integrity, positioning your operations at the forefront of aerospace innovation.

Scaling Up Production: Next-Gen ATL for High-Rate Aerospace Manufacturing

With demand for next-generation single-aisle aircraft on the rise, manufacturers face increasing pressure to ramp up production while maintaining quality and cost efficiency. Learn how the latest advancements in Automated Tape Laying (ATL) technology can dramatically boost productivity, reduce cycle times, and integrate seamlessly into existing production lines—helping you meet the demands of tomorrow’s aerospace industry today.

In-Process Composite Inspection: Ensuring Quality and Enabling Throughput

Quality control in composite manufacturing is critical—but traditional inspection methods slow down production. Discover how real-time, in-process inspection technology is transforming the industry, enabling manufacturers to detect defects on curved surfaces as parts are being produced. With automated measurement and machine learning-driven insights, this solution ensures aerospace manufacturers can achieve both high quality and high throughput without compromise.

Automating Large-Scale Composite Structures: Efficiency in Sail Mast Manufacturing

Lightweight composites are revolutionizing maritime technology, but scaling up production efficiently remains a challenge. Learn how advanced automation is transforming the manufacturing of large composite structures—like the Robotic ATLAS-R High Technology —by improving material layup precision, reducing labor-intensive processes, and accelerating production. Discover how innovative solutions from aerospace manufacturing are being applied to push the boundaries of efficiency in composite manufacturing for marine applications.

Use code "EXH1354259524" to receive a free badge for all 3-days of JEC World 2025.

Step 1: Create your account using the link below

Step 2: Scroll down to select “Buy now”

Step 3: Scroll down to finalize personal information and select “add to cart”

Step 4: Select “Finalize order” and enter promo code “EXH1354259524” to redeem your free badge!

Featured Solutions:

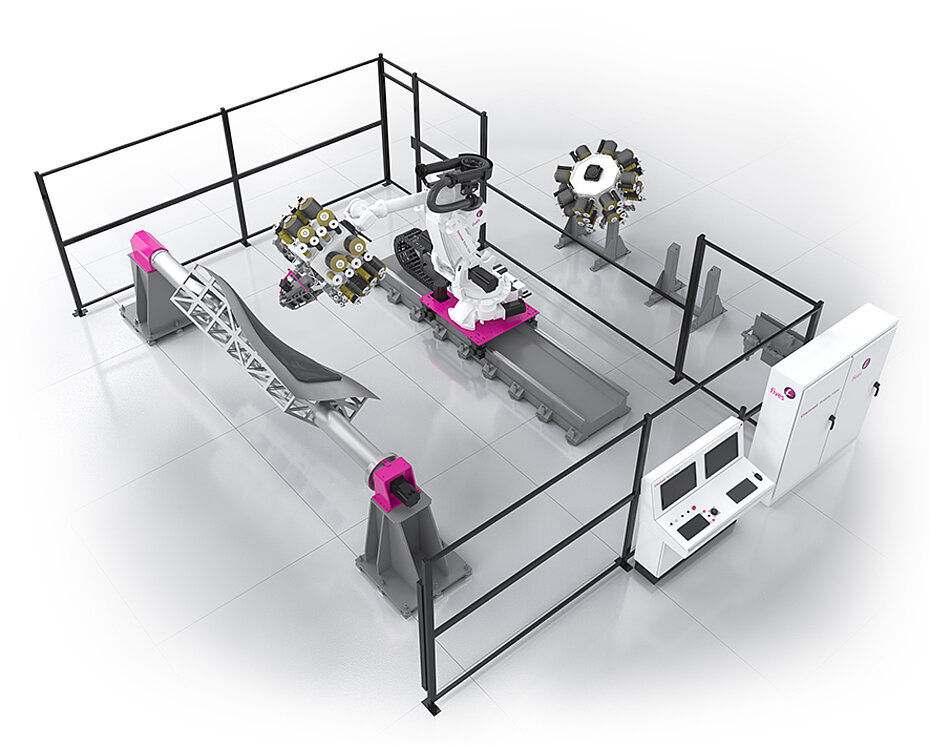

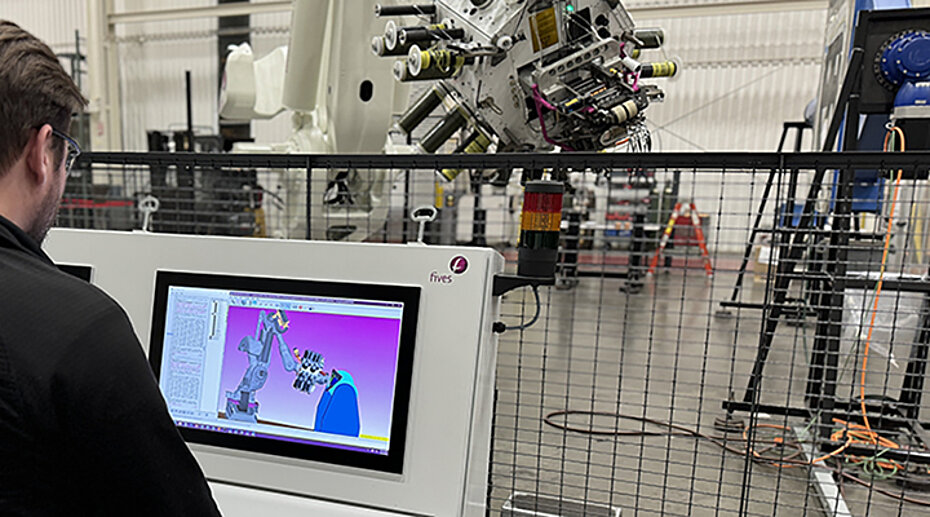

CINCINNATI ROBOTIC VIPER

Cincinnati Viper Fiber Placement Systems represent the largest install base of fiber placement machines in the world. The Cincinnati Robotic Viper combines industry leader’s expertise with next generation automated fiber placement systems, offering a solution for applications previously laid up by hand.

- High Reliability CUT/ADD Mechanisms

- Accuracy at High Laydown Rates

- Interfaces with Digital Engineering Suite

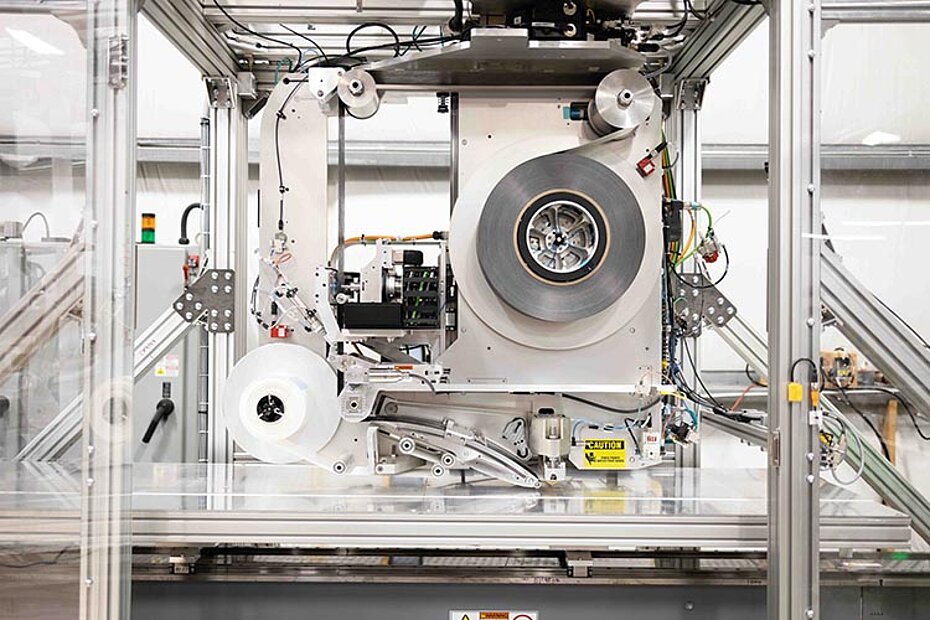

CINCINNATI SUPERCHARGER

The Cincinnati SuperCharger is the next evolution in Automated Tape Laying, providing faster, more flexible flat tape lamination on complex courses and low contours.

- Higher than 99.9% CUT/ADD Reliability

- On-head scrap management

- Cut on the fly speeds up to 1.8m/s

(Composite Optical Automated Surface Tracking)

Based on advanced Optical Coherence Tomography (OCT), COAST integrates seamlessly into the AFP machine, collecting real-time inspection data without impeding performance. Designed to handle a wide range of composite materials and sensor incident angles for advanced quality assurance.

- OCT technology creates 3D maps of composites surface

- Real-time tow placement measurement and control

- Measures close to compaction roller minimizing optical variation

ACES (Advanced Composites Environment Suite)

ACES is our proven analysis, simulation, and programming software for tape laying and fiber placement laminates. This powerful tool set is used to prove part designs, maximizing composite manufacturing performance.

- Rapid evaluation of part coverage

- Collision detection and automatic avoidance

- Evaluate fiber deviation, wrinkling, gap, and more

Composite Mast Project with SOLIDSAIL

Our collaboration with SOLIDSAIL MAST FACTORY is on track, and we’re playing a key role in the mass production of innovative 65-meter carbon masts for eco-friendly shipping!

Using our Atlas R-Cell technology, we're helping revolutionize maritime transport with cutting-edge robotized draping. This 天博体育 solution is truly a game-changer in Productivity & Performance, reducing today's takt time by a factor of 10. It enables the deposition of composite strips up to 3 meters in diameter and 65 meters long, at a high speed of 150kg per hour!

In partnership with five other visionary companies, led by Chantiers de l'Atlantique, 天博体育 Machining is playing a crucial role in this groundbreaking initiative. Our expertise in developing a robotized draping cell using Atlas head technology will contribute to the mass production of carbon masts, supporting a semi-rigid sail designed for low-carbon maritime transport.